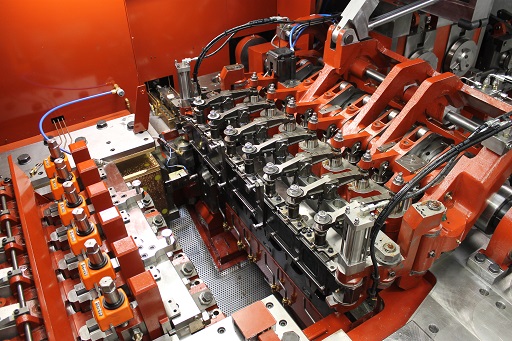

The best net shape part Formers wit 6 dies from 6mm to 33mm wire diameter.

For the production of Net Shape special parts, Sacma introduces the new release of its 6 dies progressive headers inspired by the S-Forging concept. The new touch screen panel SC-Matic is facilitating the tool set up, taking under control the process through the machine supervision and management. Sacma can guarantee the quality of the produced parts using the new LoadMatic, by monitoring the loads and driving the discharging device for the n.c. parts with the transfer fingers or a gate before the finished parts conveyor.

The Sacma Transfer System with its 7 strategies of transferring, consolidates its position of excellence, for its capacity to handle the wider range of parts, starting from shortest to the extra-long ones, at maximum production speed. The introduction of the patented Transfer Support Assist Package extends the transferring performance to more difficult tapered and stepped parts. The Timed Desmodrive cams allows the transfer of the most difficult parts adjusting the timing of departure of the transfer rack after each forging operation.

With the S-Forging concept, Sacma offers a revolutionary wire feeder: the S-Feed System. This unique and patented system allows to feed the header in the most precise and simplest way available today. The patented S-Feed System by means of one or two servomotors according the machine size, allows to engage the wire while the machine is stopped and also to pull back the wire automatically without any manual operation.

With this new device, the operator has only to set-up the length of the blank on the SC-Matic Touch Screen Panel Control and the machine takes care about the over or lower wire feeding. Another strategical point is the possibility to use the S-Feed in alternate blow mode to reduce the machine load.

The Sacma S-Forging is the result of a concentration of best technologies applied to cold and warm formers to create the most precise and reliable machines available.