No worries about secondary operation: The pointing unit SMP14.

Many screws or bolts require a chamfer or a point shape before thread rolling. There are many different types of points that can be made easily and at low cost by cutting rather than using complex and more expensive forming tooling.

The INGRAMATIC pointing unit spindle is mounted on a motorized slide so that it can easily be set on the correct position for the different lengths of blanks. This position can be memorized to speed up set up times. The blank is first placed between two fingers which clamp the part and lower it to the pointing tools, where the point is cut. The scraps are ejected with the coolant and collected in a special container where the liquid is filtered and recirculated.

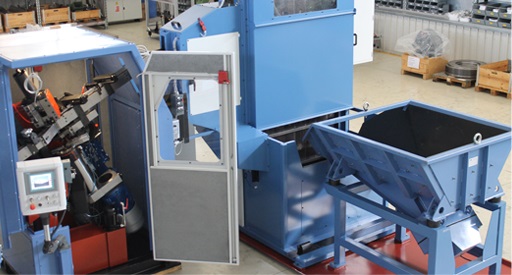

According to customer preferences, the pointing unit can be a standalone machine or a work unit integrated with the thread rolling machine to point the parts before thread rolling using the same assembly unit.

Innovative solutions: standalone pointing unit or integrated pointing system.

Make your choice…