The constant evolution of the forging world forces tool design engineers to develop tooling technology to greater levels, in order to produce always more special and difficult parts.

Today, in the planning stages of new investments, it is all the more important to be able to rely on the support of a trustworthy partner who has experience in tool design and forming progression, to develop a suitable forging method to manufacture the parts in question.

The long term experience and know-how that SACMA has of analysis of forging problems and in the research of suitable technical solutions, which are then shared with the customer, makes us a valid partner to be of assistance during the critical stages of development, to bring the project to a successful solution in the shortest possible time.

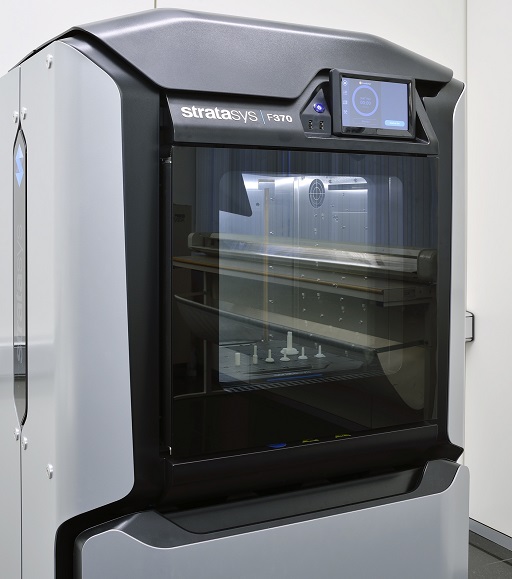

A team of project engineers, assisted by modern design and calculation software, works together with the customer to reach the best manufacturing solutions for the industrial development of the product.

With the co-operation of other leading companies in our industry, SACMA is also able to suggest efficient turn key solutions of the projects.

The changing world of thread rolling encourages designers and technicians to develop increasingly complex products using the cutting-edge technology available.

When planning new investments, it is very important to be able to count on a reliable partner who is skilled in designing and developing equipment that can satisfy special requests.

INGRAMATIC’s consolidated experience in thread rolling and search for technological solutions in close collaboration with customers make it an ideal partner at this critical stage who will help to accelerate project development times.

A team of engineers, using highly innovative simulation and design software, works together with customers to identify the best product manufacturing solutions.

By collaborating with leading companies in the field, INGRAMATIC can also offer efficient “turnkey” production systems.